Uvlack is making waves as a game-changer in surface protection, thanks to its innovative UV-cured liquid coating technology. It’s setting new benchmarks for durability, efficiency, and environmental responsibility across a bunch of industries. Honestly, it’s a big leap from the traditional coating methods we’ve seen before.

With UV-curing technology becoming more and more relevant today because of how fast and effective it is—this article dives into the key perks of Uvlack. You’ll see why it’s considered a true innovator in advanced surface coatings, offering clear benefits that many sectors can tap into.

What is Uvlack? An Overview of UV-Cured Liquid Coating

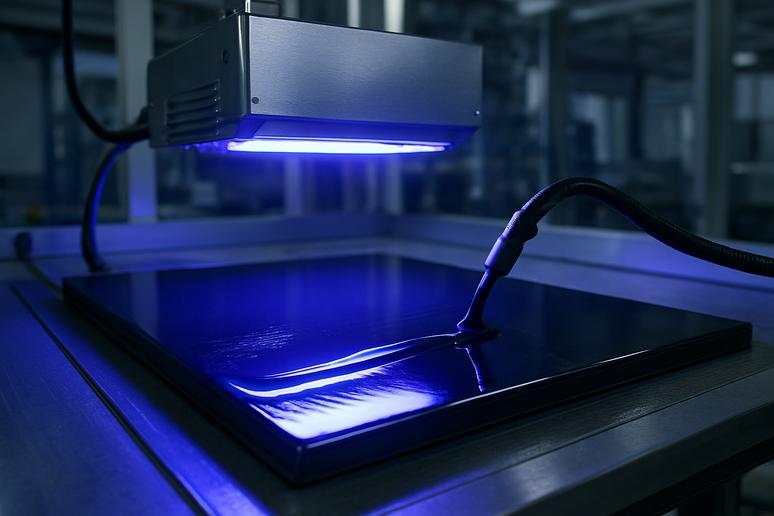

So, what exactly is Uvlack? In simple terms, it’s a super advanced UV-cured liquid coating technology designed to give surfaces an exceptional finish and protection. Unlike older coatings that rely on heat or just air drying, Uvlack uses ultraviolet light for curing. Pretty modern, right?

The “UV” part of Uvlack stands for ultraviolet, which is the heart of how it works. When those UV rays hit the coating, they quickly turn liquid polymers into a solid, super-durable film—almost instantly. This is a game-changer compared to traditional coatings that take much longer and gobble up more energy.

One of the coolest things about Uvlack is its speed and precision curing. Older coatings often emit volatile organic compounds (VOCs) as they dry, which isn’t great for health or the environment. Uvlack’s UV curing cuts down or eliminates those emissions, making it a much cleaner option.

The move toward ultraviolet coating tech is all about delivering consistent, tough protection. Uvlack is right at the forefront, giving surfaces extra resistance against scratches, chemicals, and everyday wear and tear. It’s perfect for industries that need their products to last and perform.

Key Benefits of Uvlack: Why Choose UV-Cured Liquid Coating?

Fast Curing Time and Increased Productivity

One of the biggest draws of Uvlack? Its blazing fast curing time. Thanks to UV light exposure, these coatings harden in just seconds. No more waiting hours or even days for traditional coatings to dry completely.

This quick turnaround means businesses can ramp up production, smash bottlenecks, and process more products faster. In my experience, faster curing like this can seriously streamline operations and cut down costs big time—something UK manufacturers especially value.

Durability and Superior Surface Protection

Uvlack’s coatings deliver some seriously tough protection. They create a tightly cross-linked polymer network that offers impressive hardness and scratch resistance. Basically, it makes surfaces much sturdier against everyday bumps and scrapes, extending product life significantly.

Plus, Uvlack is resistant to all sorts of chemicals and environmental nasties like moisture and UV damage. That means whatever you coat stays looking good and holds up over time—even in challenging conditions.

Environmentally Friendly and Sustainable Advantages

Here’s where Uvlack really shines for those of us thinking about the planet. These UV coating solutions usually come with low or zero VOCs, which means fewer harmful emissions pollute the air and safer workplaces for everyone.

And on top of that, UV curing uses a lot less energy than traditional thermal drying. That means smaller carbon footprints and more sustainable manufacturing. With the UK and global industries moving toward greener practices, solutions like Uvlack are becoming must-haves.

High-Quality Aesthetic Finish

It’s not just about protection—Uvlack nails the look too. The surfaces come out super glossy, smooth, and uniform, with none of those pesky defects like uneven drying or dust spots. The finish is consistently flawless and premium.

Thanks to the flexibility of the UV-curing process, you can play around with all kinds of colors and textures, from shiny gloss to soft matte. This is great for boosting product appeal and making sure your brand looks top-notch.

Applications of Uvlack Across Industries

Industrial and Commercial Uses

Uvlack coatings are all over the place when it comes to industry. In the automotive world, for example, they’re used on clear coats for plastic parts, interior trims, and headlights—helping protect against scratches and chemicals while keeping things looking sharp.

Electronics manufacturers also love Uvlack to safeguard delicate components and circuit boards. Packaging gets a boost too, with fast curing and durable finishes on labels and containers that keep products safe and visually appealing. Furniture makers rely on it as well for scratch-proof and eye-catching finishes on wood and composites.

Healthcare and Sanitation

Uvlack’s hygienic, chemical-resistant properties make it a winner in healthcare. It’s increasingly used on medical devices to create sterile, easy-to-clean surfaces that help prevent bacterial growth—which is huge for hospitals and clinics.

Hospitals, labs, and public spaces benefit a lot too. These coatings provide a tough barrier against germs and stand up to frequent cleaning with harsh disinfectants—keeping things safe and sanitary where it matters most.

Creative and Digital Markets

For creative industries, Uvlack offers a high-gloss protective finish that cranks up color vibrancy and durability—great for luxury packaging or promotional stuff. It really makes printed materials pop.

Artists and designers also appreciate it because it protects their work from wear and environmental harm while keeping finishes flawless. That means beautiful art and design pieces that stand the test of time.

Emerging Trends in Sustainable and Smart Coatings

Uvlack fits perfectly with the UK’s push toward greener industrial solutions. With low VOCs and energy-efficient curing, it’s helping companies hit their sustainability goals. So if you’re looking to position yourself as an eco-conscious business, Uvlack is a smart pick.

The Innovation Behind Uvlack: Technology & Market Potential

Here’s a bit of science behind the magic. UV-curing technology—which powers Uvlack—involves a photochemical reaction triggered by UV light. When the UV rays hit photoinitiators in the liquid coating, it sparks polymerization, instantly creating a solid, cross-linked film without the need for heat or solvents.

Uvlack takes this technology to the next level by optimizing for superior performance. It’s a clear step up from older, slower drying methods that were also more harmful to the environment. This advanced approach gives you faster, stronger, and cleaner results.

The market for advanced UV-curing tech like Uvlack is booming, both in the UK and worldwide. Demand for quicker production times, tougher coatings, and greener processes is driving growth. UK industries adopting these solutions are gaining a real competitive edge.

What’s next? Researchers are working on even smarter coatings—think self-healing surfaces or integrated sensors—which means the future looks bright for innovations building on Uvlack’s technology.

How Uvlack Supports Brand Identity and Marketing

Using Uvlack isn’t just a technical choice; it’s also a solid marketing move. Featuring Uvlack in your products sends a clear message about your commitment to high-tech quality and innovation. It can really help your brand stand out in crowded markets and attract customers who appreciate premium finishes.

Associating with UV-cured coatings like Uvlack also boosts your brand’s image around modernity, sustainability, and quality. If your customers care about the environment—and many do—you’re showing that you’re on the right side of that conversation. That’s priceless for reputation and trust.

Plus, the visual story Uvlack tells—fast curing, superb protection, brilliant finishes—makes for great content in marketing campaigns. It communicates reliability and excellence clearly and powerfully.

Conclusion

All in all, Uvlack is a real breakthrough in the world of surface coatings. Its blend of rapid curing, outstanding durability, and serious environmental benefits is reshaping what’s possible in industrial and commercial settings. It’s a smarter, cleaner, and stronger solution that ticks all the boxes.

The impact across industries is huge: from automotive parts to medical devices, Uvlack offers a coating that’s ready for the future, meeting today’s manufacturing demands while being kinder to our planet.

If you’re a business or innovator in the UK considering your next step in surface coatings, seriously think about Uvlack. Embracing this advanced UV-cured liquid coating means investing in efficiency, premium quality, and a greener tomorrow. It’s a step that puts your company at the forefront of innovation and responsible manufacturing.